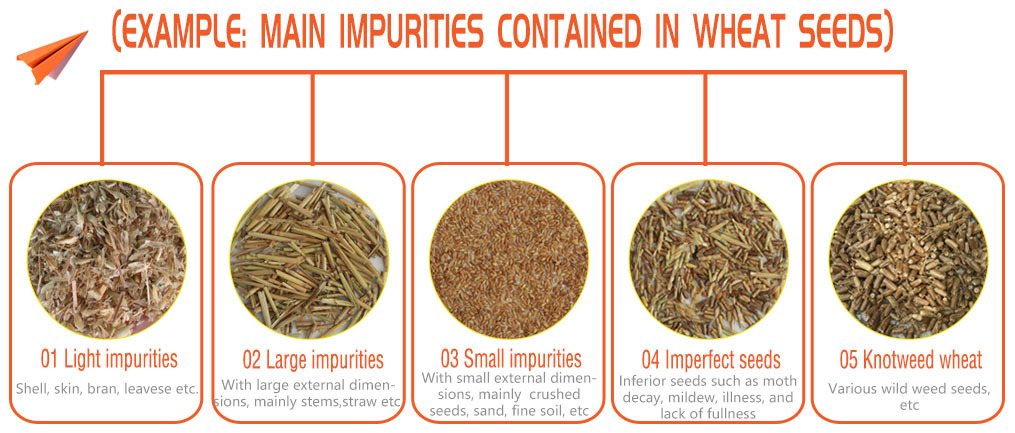

After harvest, seeds often contain a large amount of impurities, broken seeds, and shriveled seeds, which need to be removed in order not to affect the quality of the seeds. The selective processing process of seeds can effectively remove impurities such as sand, plant debris, insect eggs, weed seeds, and other impurities mixed in the seed raw materials

After harvest, seeds often contain a large amount of impurities, broken seeds, and shriveled seeds, which need to be removed in order not to affect the quality of the seeds. The selective processing process of seeds can effectively remove impurities such as sand, plant debris, insect eggs, weed seeds, and other impurities mixed in the seed raw materials, while separating seeds that are not full, broken, or of poor quality, thereby improving the purity of the seeds. Reasonable selection and utilization of the process of selecting and grading seeds can effectively improve the purity, germination rate, and vigor of seeds.

After processing, the seeds are plump, uniform in size, with few impurities, high germination rate, and good purity. In particular, coated seeds can prevent the erosion of pests and diseases. When sown in the field, the uniformity of crop emergence and growth is better, and it is conducive to mechanized operations and provides labor efficiency.

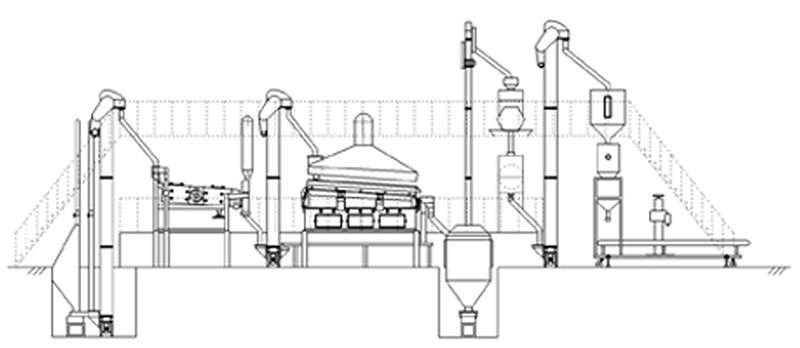

Any combination, each unit of equipment can work independently

★ Design and processing capacity:5~10 t/h

★ High cleanliness: scientific and reasonable equipment configuration to ensure the processing effect

★ Low crushing: adopt double drum bucket elevator, low broken

★ Workflow integration: simple operation and labor saving

★ Dust removal and environmental protection: perfect dust removal system to ensure good dust removal effect

★ Wide applicability: seeds such as maize, wheat, beans, vegetables, and other grains can be processed

★ Various types of fixed and movable seed/grain production lines can be customized according to user needs.

Processing Demand Survey