The 5XZC-7.5DXA Air screener um grader has 4 layers sieve, With a very wide range of sieves available, this machine is very versatile and can be used for seed cleaning of almost all crops.

The 5XZC-7.5DXA Air-screener has 4 layers sieve, with a very wide range of sieves available, this machine is very versatile and can be used for seed cleaning of almost all crops.

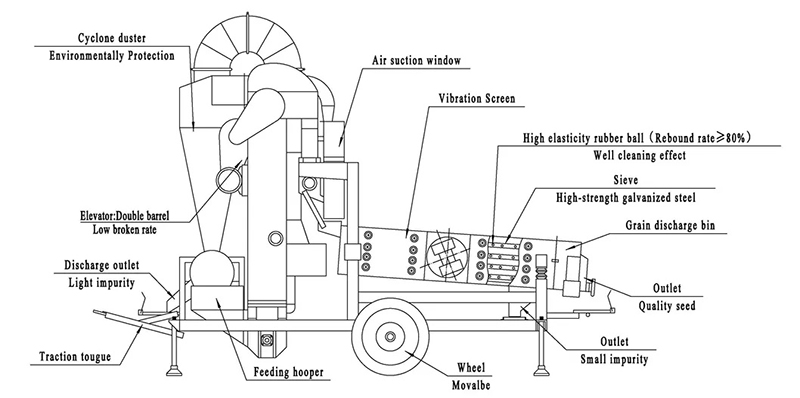

The machines sift based on aerodynamics and the surface speed difference of seed and impurities, adjusting the seed of the air current. As impurities are light, they are sucked into the cyclone duster, while seed is heavy and is transferred into a vibrating screen. The vibrating screen has four layers sieves with five outlets which eject large impurities, small impurities and seed respectively, the vibration screen used for separating seeds according different sizes.

1.The machine works with 4 sieve levels, The sieve are cleaned on ball frames, with rubber balls.

2.The rubber ball sifting structure complies with international standards, highly elastic, endures and long lasting.

3.The sieves are tightly fit in the machine by a clamp-locking system for quick changing of the sieves and thorough cleaning of the machine.

4.The volume of air is variable and adjusted from minimum to maximum by a controlling handle, assuring very accurate cleaning and sorting of seeds. The blower has a very stable and reproducible output.

5.Transparent inspection windows for easy inspection and clean out.

6.The machine has a very low noise level.

7.Very easy and thorough cleaning of the machine and no contamination risk.

8.No wooden frames on the sieves where seeds can hide.

9.With cyclone duster, environmentally friendly model.

Feeding and Air-suction.

Put the seeds into feeding hopper, through bucket elevator the seed are transported to the air-suction channel, and then drop to the first sieve. The Air suction volume is adjustable by hand very easy and accurate separation without loss of seeds in the air flow. In the air-suction, the seeds are sorted by weight, the dust and lightest impurity are carried upwards with the air stream and fall down in the dust collector. The heavy seed will fall down in the firstly layer sieve.

Sieving(4 layers sieve).

The overflow impurity which large than good seeds from first sieve leaves the machine and discharge to the outlet. The seeds dropped through fall on the second sieve for the next sieving. The overflow of the second sieve leaves the machine at the outlet, The seeds dropped through fall on the third and bottom sieve, which can grade the seeds according to thickness or width. The impurities that was smaller than the desired size of seed drop through the bottom sieve and are eliminated through outlet. The overflow seeds of third and bottom sieve have the desired size and are transported to the front outlet of machine

Model | 5XZC-7.5BXA | 5XZC-7.5DXA | |

Max-feeding Capacity | Wheat seed | 6000-7500 Kg/h | 6000-7500 Kg/h |

Maize seed | 5200-7000 Kg/h | 5200-7000 Kg/h | |

Soybean | 5000-6000 Kg/h | 5000-6000 Kg/h | |

Sesame | 1500-2000 Kg/h | 1500-2000 Kg/h | |

Size (L×W×H) | 4630×2100×3200mm | 4630×2100×3200mm | |

Sieve size(L×W) | 2400×1250mm | 2400×1250mm | |

Sieve Layers | 3 | 4 | |

Weight | 1800 Kg | 1850 Kg | |

Power supply | 380V/50Hz/3-Phase | 380V/50Hz/3-Phase | |

Total power | 8.1 kW | 8.1 kW | |

Selection rate | ≥98% | ≥98% | |

Clarity | ≥97% | ≥97% | |

Broken rate | ≤0.2% | ≤0.2% | |

Remarks | With Cyclone duster | With Cyclone duster | |

Note: The capacities may vary depending on seed condition, moisture content, seed varieties, types and volumes of contaminants to be separated and percentage of foreign material acceptable in the final product.

![]()

Processing Demand Survey